Our high-performance STRUX® fasteners offer a stronger and more reliable assembly alternative to traditional clinch studs and nuts. Along with stud and nut applications, the STRUX® design can be applied to joints that require self-tapping fasteners. In most cases, a STRUX® fastening solution will yield significant time and cost savings when compared to welded or other staked fasteners.

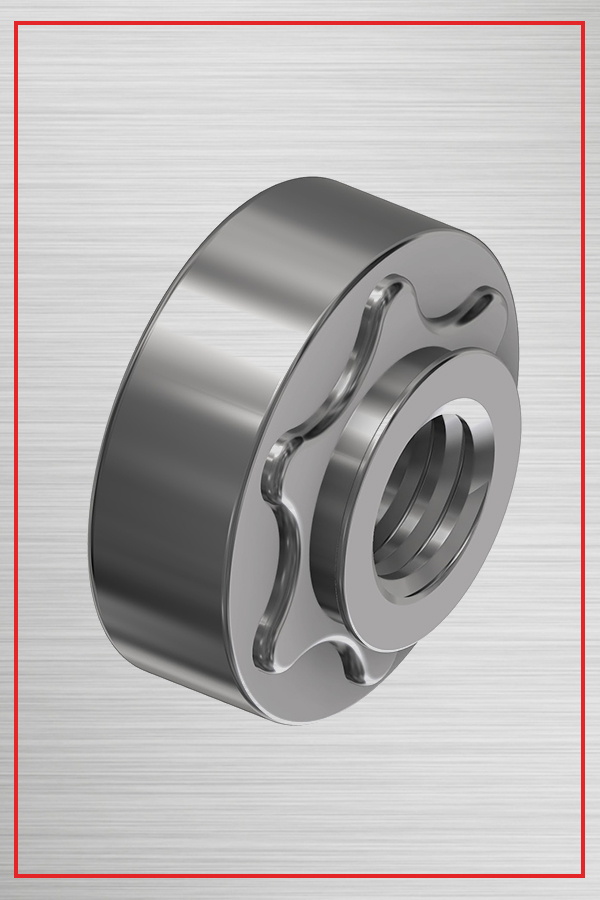

STRUX® Stud Benefits

- May replace larger diameter, conventional weld or other non-heat treated studs

- Resist push-out and rotation during service

- Eliminates hazardous welding operations and provides a cleaner appearance than welded fasteners

- Improved centerline-to-centerline tolerances compared to weld studs

- Lowers in-place costs and maximizes assembly flexibility

- No distortion due to excessive heat and increased production rates when using progressive dies

- Improved product and joint integrity

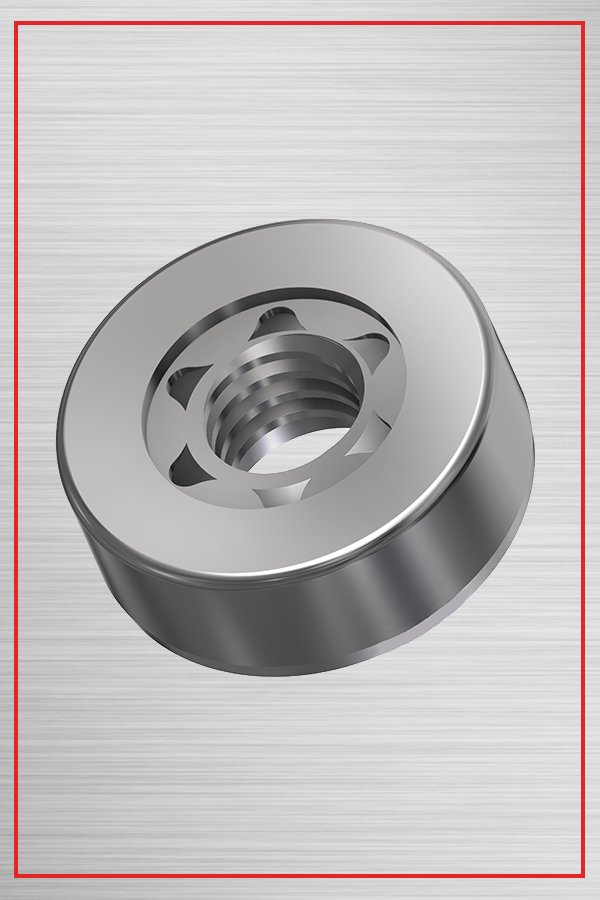

STRUX® Nut Benefits

- May replace larger diameter, conventional weld or other non-heat treated nuts

- Resist push-out and rotation during service

- Eliminates hazardous welding operations and provides a cleaner appearance than welded fasteners

- Improved centerline-to-centerline tolerances compared to weld nuts

- Lowers in-place costs and maximizes assembly flexibility

- Cross-threading and other problems caused by coated or painted threads can be prevented

- No distortion due to excessive heat and increased production rates when using progressive dies

- Improved product and joint integrity

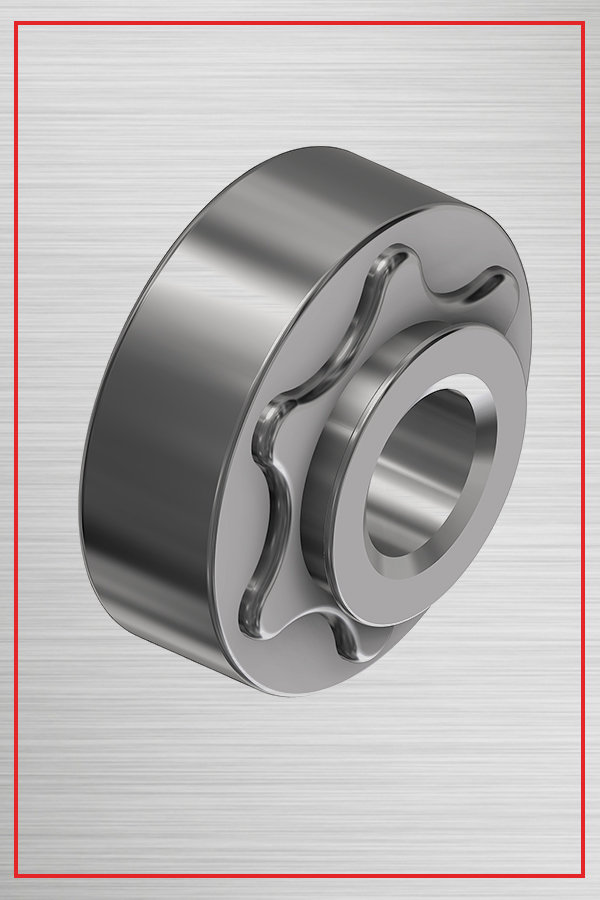

STRUX® PrevalokTM Benefits

- Allows the engaging bolt to be started before the locking action begins, assuring fast, easy installation in addition to increased product integrity

- Increased resistance to vibration loosening, which helps the joint to remain secure

STRUXTITE® Nut Benefits

- Use in conjunction with Taptite® thread forming fastener

- Prevent cross-threading and other problems caused by coated or painted threads