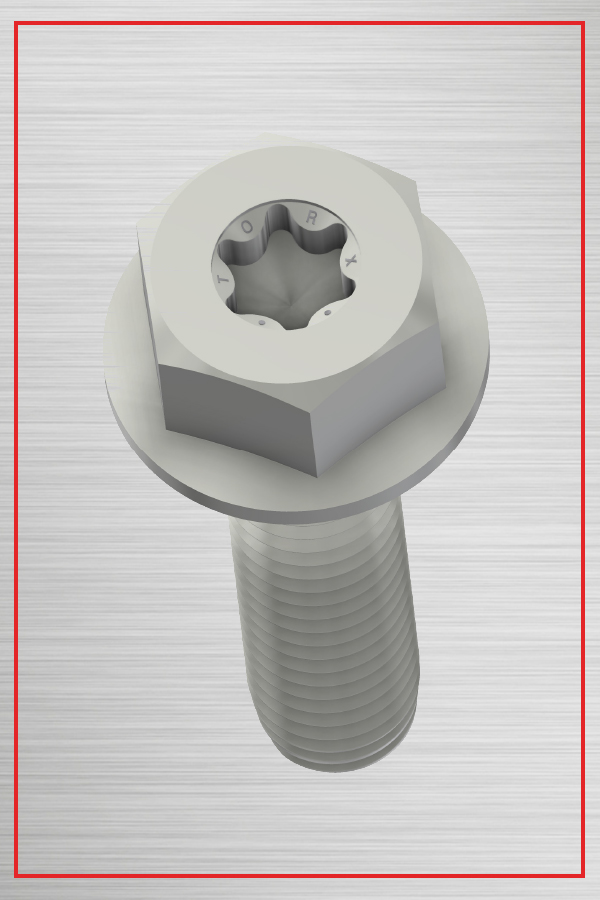

The TORX® Drive System was specifically designed to provide a simple, cost-effective solution to the problems inherent in the process of installing and removing fasteners. Used in a multitude of industries, the TORX® Drive System can enhance product reliability, increase productivity and reduce total assembly costs – all of which are keys to remaining competitive in today’s marketplace.

TORX® INTERNAL BENEFITS

- Greater depth of tool and lobe engagement while minimizing tool slippage

- No camout forces are created to push the driver up

- Since camout is virtually eliminated, little to no end load is required

- High torque transfer and drastically reduced radial forces resulting in longer tool life

- Driving forces spread over a broad surface

- Same drive systems can be used for both metric and imperial screws thereby reducing number of drive tools

- Quality enhanced through single sourced gaging program

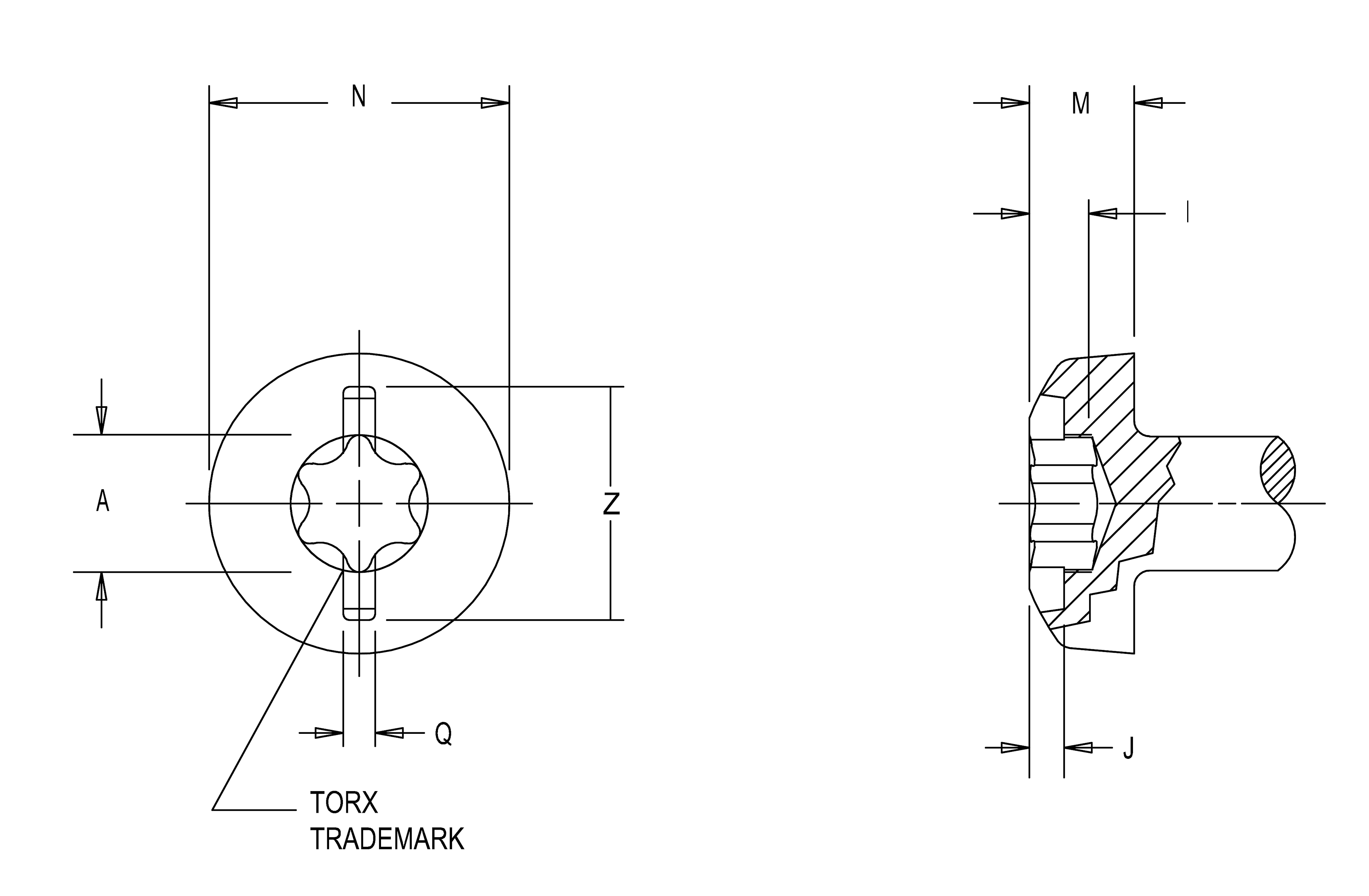

TORX® EXTERNAL BENEFITS

- Provides an excellent alternative to hex or 12-point drives

- External TORX® sockets are smaller in diameter than standard hex sockets used for the same-size fastener

- Provides greater flexibility when designing for drive socket clearance

TORXALIGN® BENEFITS

The special TORXALIGN® bit is designed with a slight taper to provide a wedging effect when the bit is inserted into the fastener recess. This is particularly useful in holding nonmagnetic fasteners on the driver during manual installation.

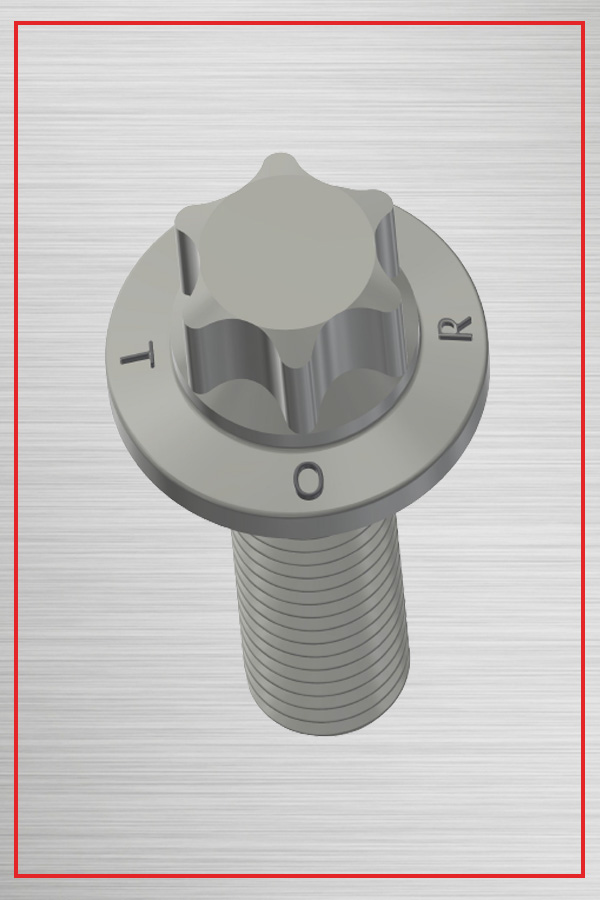

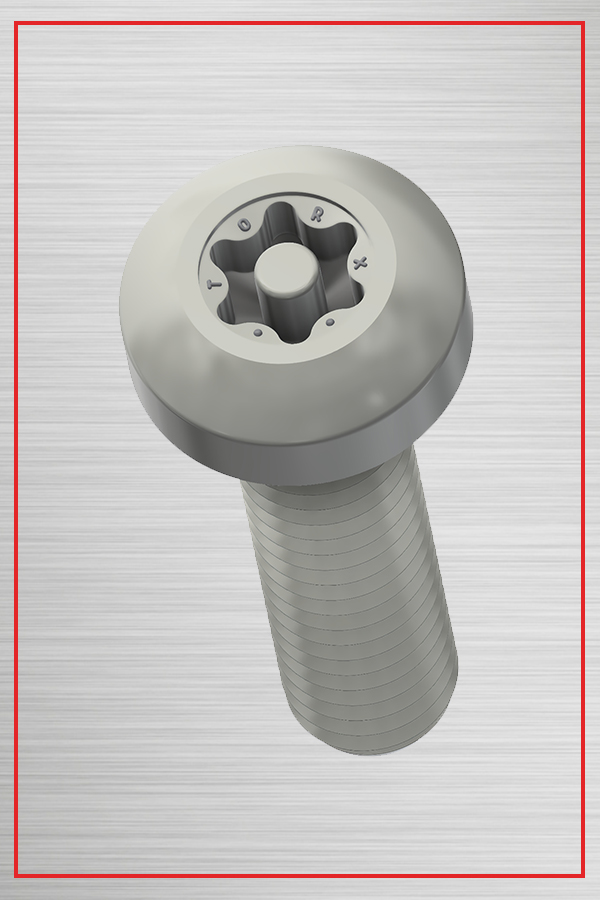

TORX® TAMPER RESISTANT/ RESISTORX® BENEFITS

This unique TORX® variation incorporated a solid post formed in the center of the recess during the heading process. When combined with a countersunk or button head design, the fastener is extremely difficult to remove without a special tamper-resistant TORX® Drive tool. Unlike other tamper-resistant fasteners, installation on the production line is easy with the proper tool.

AUDITORX® BENEFITS

Automatic torque monitoring is made possible by the AUDITORX® Drive head which is designed to break off a predetermined torque level. The standard AUDITORX® Drive leaves a hex drive for later field service. The tamper-resistant AUDITORX® Drive fastener leaves a rivet-like head to prevent removal.

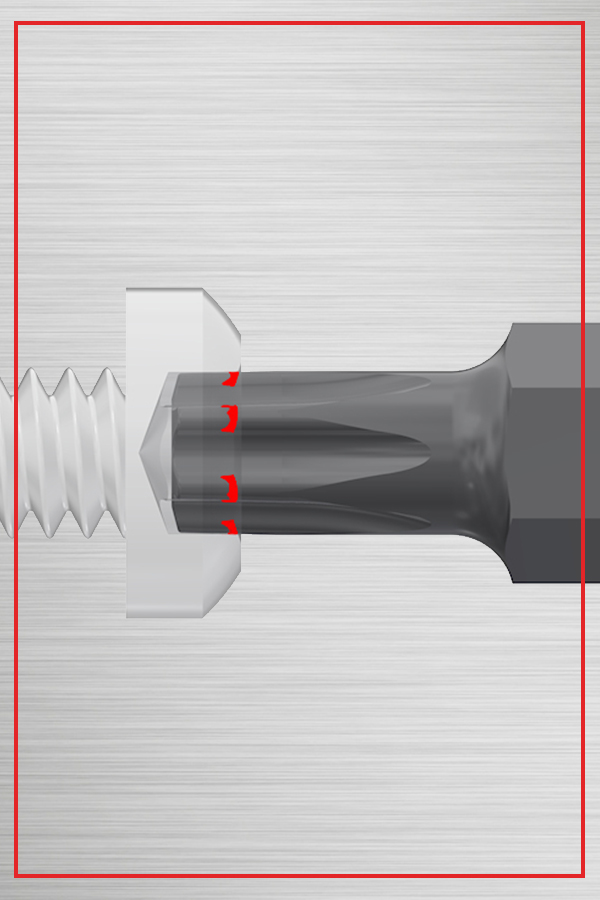

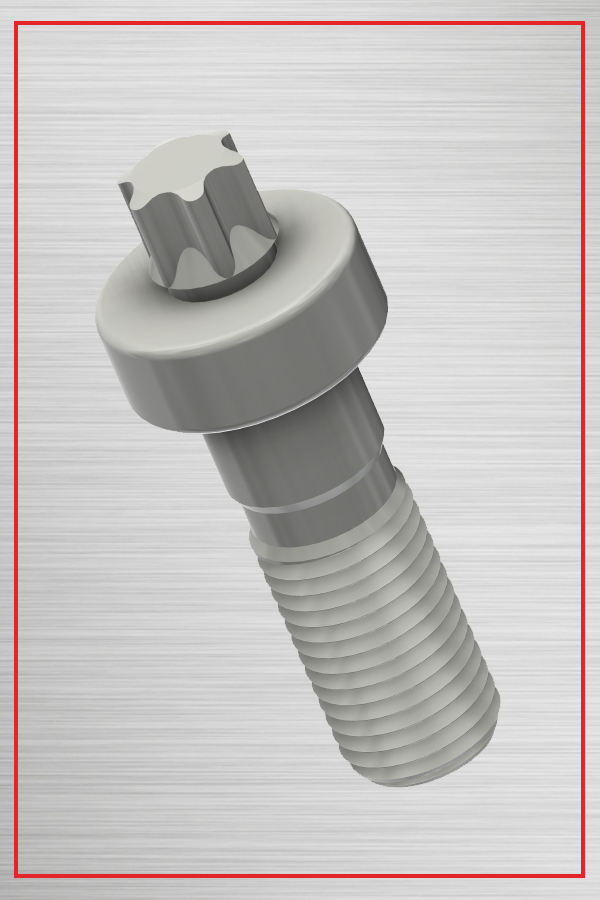

TORXSTEMTM BENEFITS

The TORXSTEM™ is primarily used in Double-end stud applications but can also be used for hold and drive applications. Since most double-end studs lack a drive system, it is necessary to grip the threaded portion of the stud in order to drive it, which can result in thread damage. A special external TORX® configuration extruded onto one end of the double-end stud simplifies driving. We refer to this as a TORXSTEM™ Double-end stud. They are installed using a TORX® socket to increase productivity and reduce thread damage.

TORX® DUAL DRIVE BENEFITS

The TORX® Drive System can be combined with either an external hex or a slot to provide a dual drive system.

- This provides the option of driving or removing the fastener with commonly available TORX® tools or with a hex socket or slotted screwdriver

- The slotted TORX® recess has a slot which is enclosed at the ends, so the driver is less likely to slip out and damage the surrounding surfaces

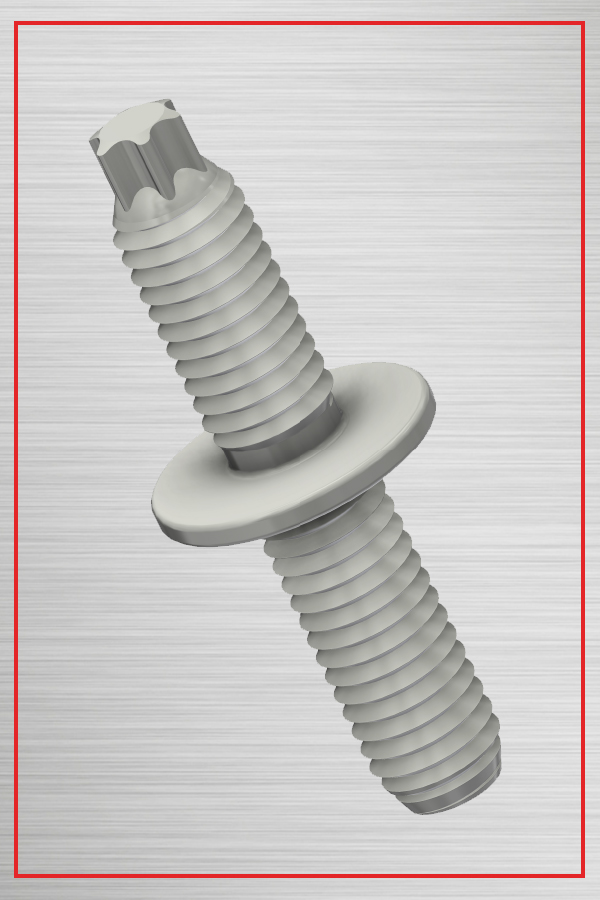

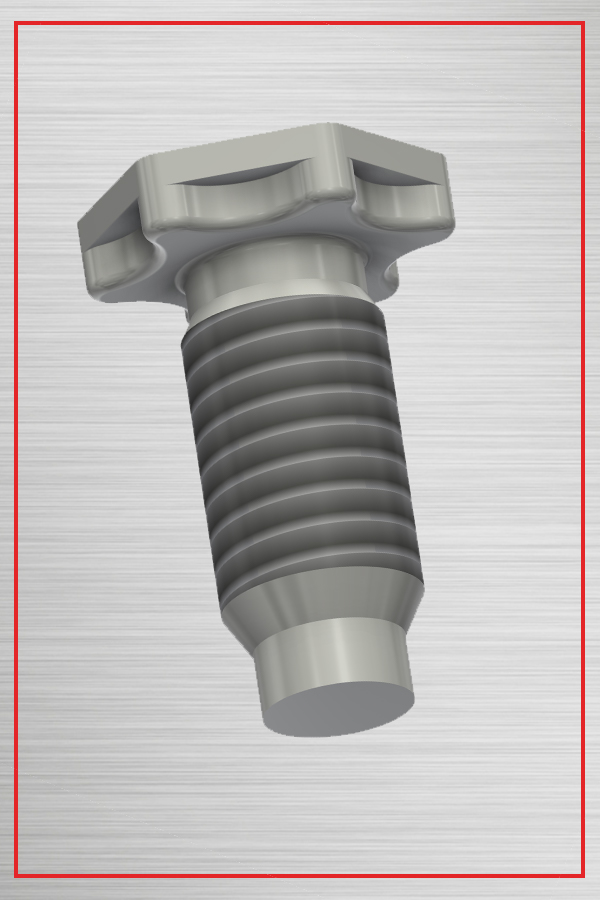

PlasTORX® BENEFITS

- Molded directly into application which increases assembly efficiency

- Provides maximum resistance to rotation and pull-out

- Can be used in materials susceptible to cracking

TORX® configuration allows deep lobe engagement

- Increases torsional resistance

- Increases pull-out resistance

- Reduces stress risers

Flange on top of head enhances performance

- Increases pull-out resistance

Threaded shaft for seating nut member

Designed to be molded directly into component or carrier strips, allowing multiple fasteners to be installed at one time

- Reduces assembly time

- Reduces part numbers and associated costs

- Reduces overall costs