ClearDrive®

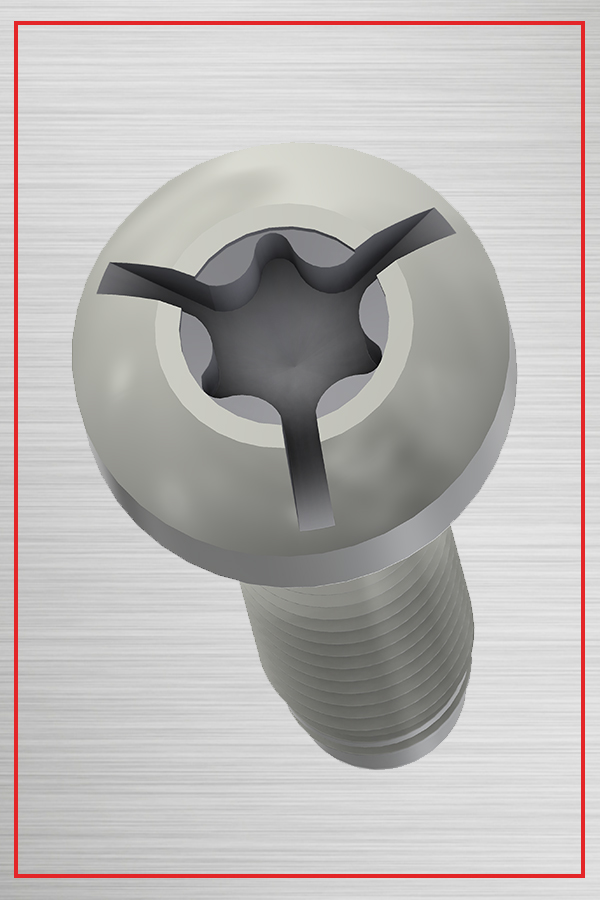

Over the last 40+ years, the TORX® drive system has proven to be a remarkable and reliable drive recess that is found in products all over the world’s marketplace…and it is still growing! But while the product has proven itself, a new improvement on the system has been developed. It is called the ClearDrive® feature. The ClearDrive® feature was developed and patented by Illinois Tool Works (ITW) to solve the problem of organic coatings that would fill the recess during the dip-spin process, thereby compromising the drive system. ClearDrive® allows the coatings to escape from the recess via the channels added to the TORX® recess, virtually eliminating recess-fill. As a 2011 PACE Award Finalist, the design has been well received in the industry and rapidly gaining attention as it is proving to reduce manufacturing costs as scrap and sorting are dramatically reduced.

TORX® ClearDrive® BENEFITS

- Flutes aid in drainage of excess coating

- Significant savings of 8%-18% are achievable through elimination of special processing and sorting.

- Parts converted to the ClearDrive® feature will see further improvements to the bottom line through the elimination of scrap

- Reduces assembly damage with improved bit engagement

- Use dip-spin instead of Alloy Electroplating

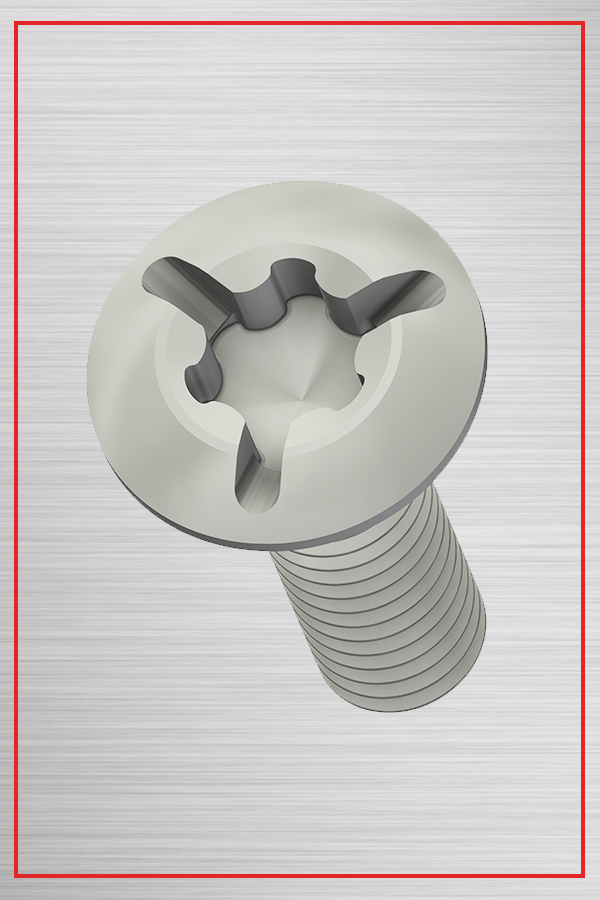

TORX PLUS® ClearDrive® BENEFITS

- Elliptically – based Geometry

- Broaden contact surface to maximize engagement of driver and recess

- Eliminates damaging point-to-point

- Broaden contact surface to maximize engagement of driver and recess

- 0o Drive Angle

- Optimizes torque transmission

- Virtually eliminates radial stresses to increase tool bit life

- Allows use of thinner-walled recesses

- Optimizes torque transmission

- Six Lobes With Larger Cross-Sectional Areas

- Allows faster tool engagement

- Maximizes Torque Transfer

- Increases torsional strength

- Allows faster tool engagement

- Greatly Increased Strength and Reliability

- 100% average improvement in driver bit life; many users of the TORX PLUS® Drive System have driven 2 to 10 times more fastener per drive tool

- 25% average improvement in driver bit torsional strength

- Increased bit strength allows for higher removal torque capability

- 100% average improvement in driver bit life; many users of the TORX PLUS® Drive System have driven 2 to 10 times more fastener per drive tool

- Flutes aid in drainage of excess coating

- Significant savings of 8-18% are achievable through elimination of special processing and sorting.

- Parts converted to the ClearDrive® feature will see further improvements to the bottom line through the elimination of scrap.

- Reduces assembly damage with improved bit engagement

- Use dip-spin instead of Alloy Electroplating