Trusted R&D Source for the Fastener Industry

ABOUT US

CAMCAR Innovations® specializes in Research & Development of fasteners, continually striving to solve the engineering challenges of today and tomorrow. Founded in 1943, our tradition of innovation has made us global leaders in advanced technological solutions for cold forming manufacturers.

Our vision is to improve assemblies worldwide. Our mission accomplishes this goal by providing our network of authorized manufacturers with advanced products that allow them to bring differentiated functionality and manufacturability to the market. Quality is at the heart of our entire program, and we are committed to ensuring our high standards are upheld by our global network of authorized, high-caliber manufacturers.

Partnership enables our success. We partner with fastener users to help them with solutions to tough product engineering challenges as well as creating products that help speed their assembly, we partner with fastener makers to assist in their growth, and we partner with companies that have developed technologies that fulfill our vision and mission by making their products accessible globally.

Whether you design, make, or consume fasteners, we are always open to dialogue and ready to support your needs. Reach out to us, our door is always open.

Trusted R&D Source for the Fastener Industry

ABOUT US

CAMCAR Innovations® specializes in Research & Development of fasteners, continually striving to solve the engineering challenges of today and tomorrow. Founded in 1943, our tradition of innovation has made us global leaders in advanced technological solutions for cold forming manufacturers.

Our vision is to improve assemblies worldwide. Our mission accomplishes this goal by providing our network of authorized manufacturers with advanced products that allow them to bring differentiated functionality and manufacturability to the market. Quality is at the heart of our entire program, and we are committed to ensuring our high standards are upheld by our global network of authorized, high-caliber manufacturers.

Partnership enables our success. We partner with fastener users to help them with solutions to tough product engineering challenges as well as creating products that help speed their assembly, we partner with fastener makers to assist in their growth, and we partner with companies that have developed technologies that fulfill our vision and mission by making their products accessible globally.

Whether you design, make, or consume fasteners, we are always open to dialogue and ready to support your needs. Reach out to us, our door is always open.

Lightweighting

There has been a huge push in the last decade to reduce the weight of products for the purposes of cost reduction, smaller impact on the environment, increased efficiency etc.

CAMCAR Innovations® has a number of products to help achieve lightweighting initiatives.

Lightweighting

There has been a huge push in the last decade to reduce the weight of products for the purposes of cost reduction, smaller impact on the environment, increased efficiency etc.

CAMCAR Innovations® has a number of products to help achieve lightweighting initiatives.

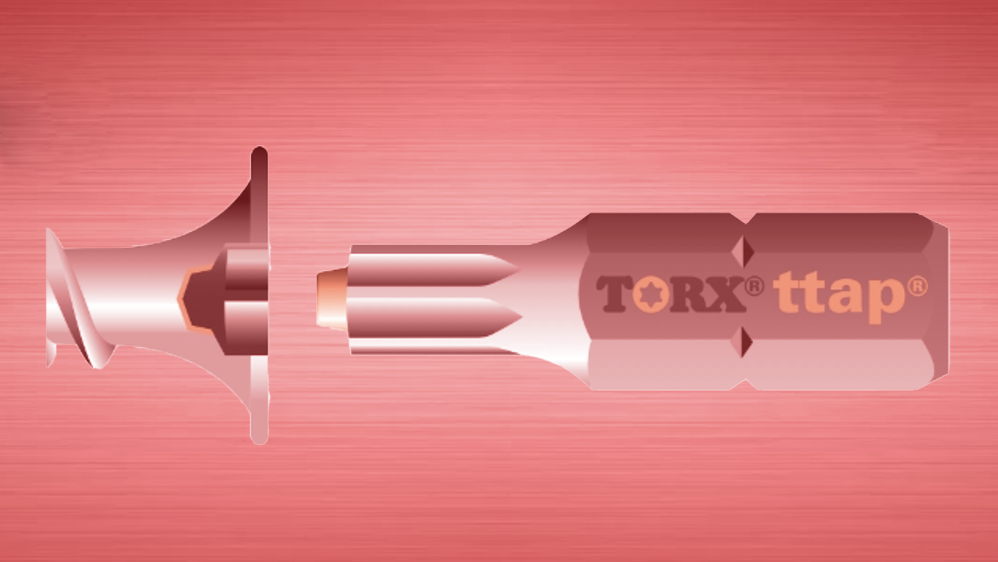

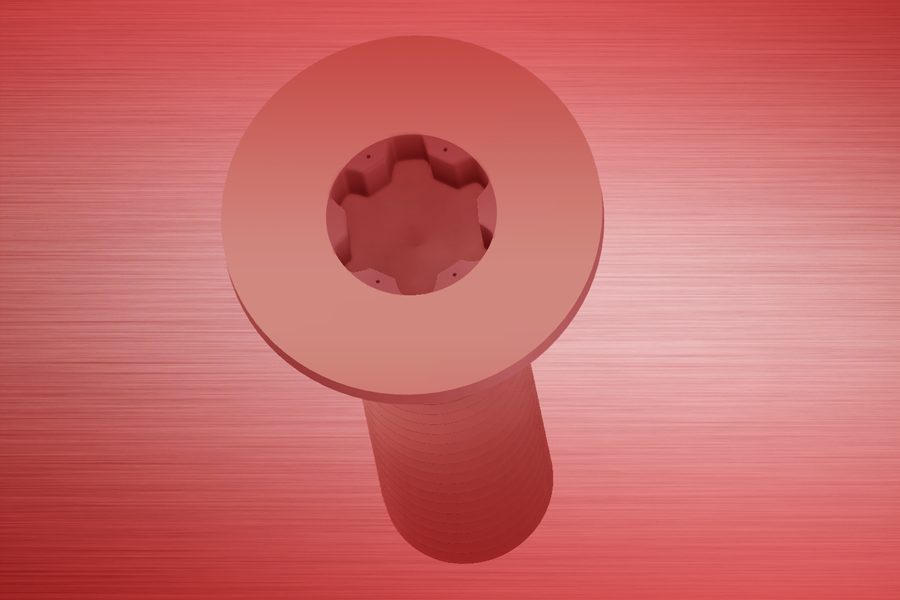

Assembly Efficiency

Improving assembly efficiency has been a cornerstone of the products we have developed, starting with TORX® Drive System which increased the amount of torque that could be applied to a screw with little to no endload and increased the drive tool life for end-users. The evolution of the TORX® Drive System led us to the TORX PLUS®Drive System which increased the ability to transfer torque by 20% and increased drive tool life by 2 to 10 times. The latest evolution of the Famous Torx® Drive system is the TORX PARALOBETM Drive System which increased the ability to transfer torque by 20% over TORX PLUS® and increased drive tool life by 100%. For these Drive Systems we have created stick fit driver bit designs to aid in assembly. Additionally the AUTOSERT® feature was developed for TORX PLUS® and TORX PARALOBETM Drive Systems which allows for higher rpm engagement of the drive tool, reducing assembly time and increasing productivity.

The Strux® family of clinch studs and nuts allow stamping suppliers to provide a fastener staked into their product reducing the handling and assembly cost.

See our Products section for more information on how each of our products makes assembly more efficient.

Our 50+ Year Licensees

| Authorized manufacturer | Initiation Date | Years |

|---|---|---|

| APEX Tool Group | 2/20/1967 | 57 |

| ITW Buildex | 1/1/1968 | 56 |

| ITW Shakeproof (auto) US | 1/1/1968 | 56 |

| Header Die & Tool, Inc. | 11/27/1968 | 56 |

| SPS Technologies | 1/19/1970 | 54 |

| Stanley Tool | 3/30/1970 | 54 |

| Linread Limited (aka Arconic Fastening Leicester | 8/3/1970 | 54 |

| Robert Bosch | 1/3/197 | 52 |

| ITW Rivex | 10/11/1972 | 52 |

| Gosho Works | 4/23/1973 | 51 |

| Meira Corporation | 4/23/1973 | 51 |

| Owari Precise Products Co. | 4/23/1973 | 51 |

| Aoyama Seisakusho Co. | 4/23/1973 | 51 |

| Nissan Screw Co. | 4/23/1973 | 51 |

| Nitto Seiko | 4/23/1973 | 51 |

| Saga Tekkohsho | 4/23/1973 | 51 |

| Topura Co. | 4/23/1973 | 51 |

| Yamashina Corporation | 4/23/1973 | 51 |

| Air Industries Company | 5/7/1973 | 51 |

| Snap-On Inc. | 5/18/1973 | 51 |

| SFS intec AG | 11/7/1973 | 51 |

| PB Fasteners | 5/31/1974 | 50 |

| NHK Precision Co. | 8/23/1974 | 50 |

LATEST NEWS