Aerospace Companies Reduce Repairs and Worker Injuries by changing to TORX PLUS®

04/11/2021

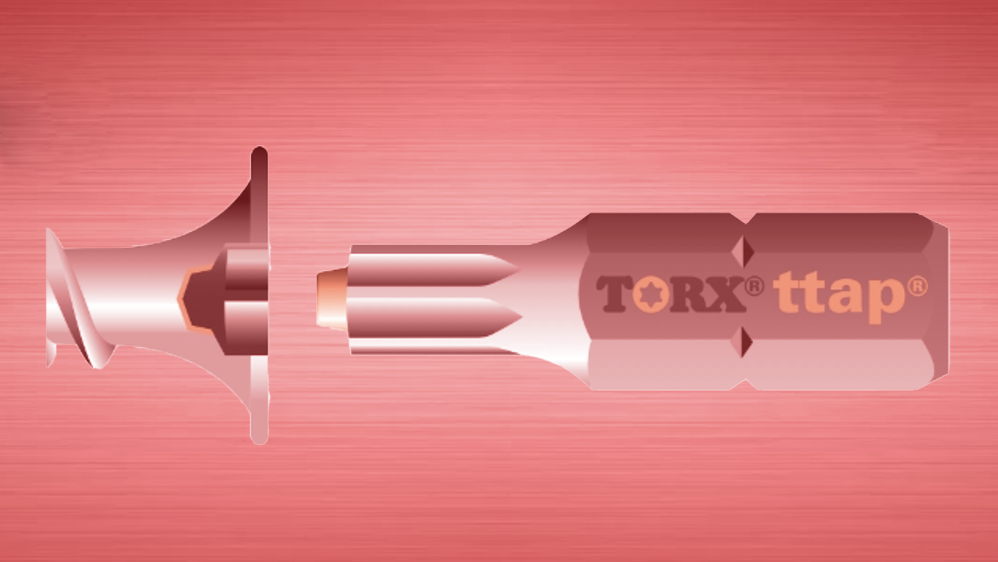

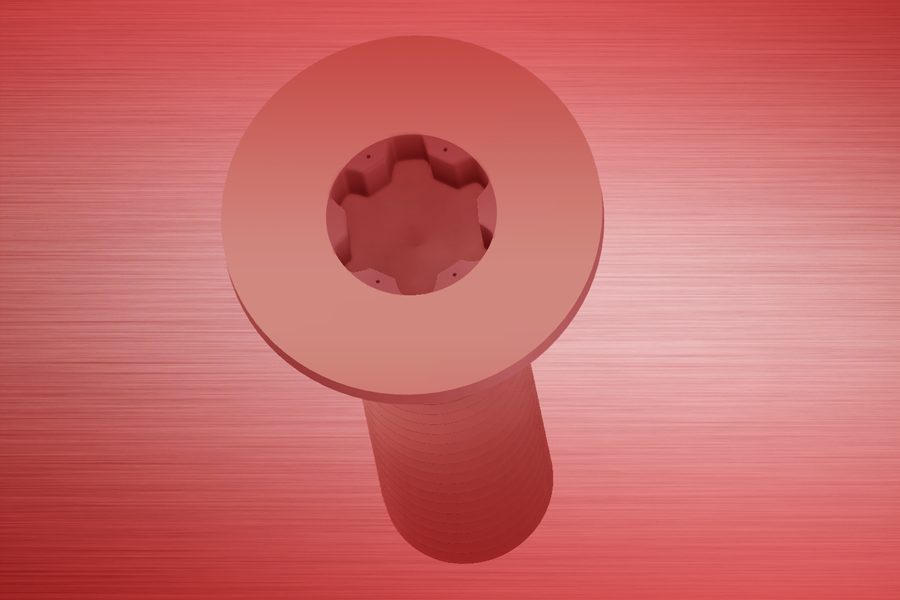

TORX PLUS® has been in use in aerospace for many years. What is the reason? To start, TORX PLUS® can transmit higher torques compared to other drive systems and do it without cam-out. Eliminating or reducing cam-out is an important safety advantage in airplane assembly. Many fasteners are installed off-axis by the assembly worker due to difficult to reach locations. With other fastener drives, the drive bit may slip out of the fastener causing the assembly worker to sustain injuries and causing damage to surrounding structures creating repair costs. TORX PLUS® eliminates these problems.

To improve assembly operations and aircraft design even further, CAMCAR InnovationsSM developed the next generation in the TORX® family named TORX PARALOBETM . It has 20% higher torque capability than TORX PLUS® making it especially useful in structural applications. It also has 20% higher drive strength. The first TORX® PARALOBETM standards have been released by SAE® Committee E-25 for engine applications resulting in the first projects with a large aerospace engine maker. We are also actively participating in the National Aerospace Standards Committee helping to update existing standards and have a new active project with the ISO® aerospace committee. As a key enabler in aerospace assemblies, we welcome the opportunity to help you reduce your overall costs so you can be more competitive.

Contact us or visit our website www.camcar.com and see how we can help you save cost, improve design, and reduce repairs and workforce injuries.